What Machine is Used to Drill Wells?

In the world of water extraction and aid exploration, one question is fundamental: what machine is used to drill wells? The reply lies in a powerful, engineered marvel known as a water nicely drilling rig. These specialized machines are complex portions of equipment designed to penetrate deep into the earth to access fundamental water reserves. Modern rigs, like the one described with a 78kW high-horsepower engine and a high-focus powerhead. For these in need of such robust machinery, discovering the right well drilling equipment for sale is the fundamental first step in any successful project.

The Heart of the Rig: Unmatched Power and Performance

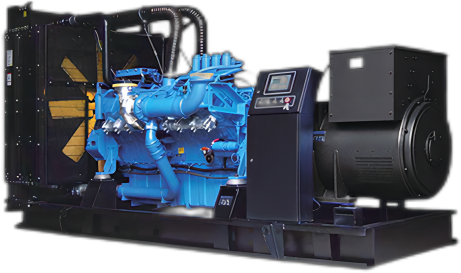

At the core of every advantageous drilling operation is raw, dependable power. The engine is the literal heart of the rig, pumping strength to every other component.

The 78kW High-Horsepower Engine

A 78kW high-horsepower engine is no longer simply an accessory; it is the foundation of the total machine. This level of energy ensures that the rig can operate constantly under immoderate loads and in difficult conditions. Whether drilling thru dense rock, clay, or sand, a effective engine provides the integral torque and rotational force to force the drill string deep into the floor barring stalling or losing efficiency. When looking for well drilling equipment for sale, the engine's specifications ought to be your primary concern. A robust engine interprets to less downtime, greater drilling depth capabilities, and the capacity to use larger, more effective drilling tools. It’s the distinction between completing a job on schedule and going through costly delays.

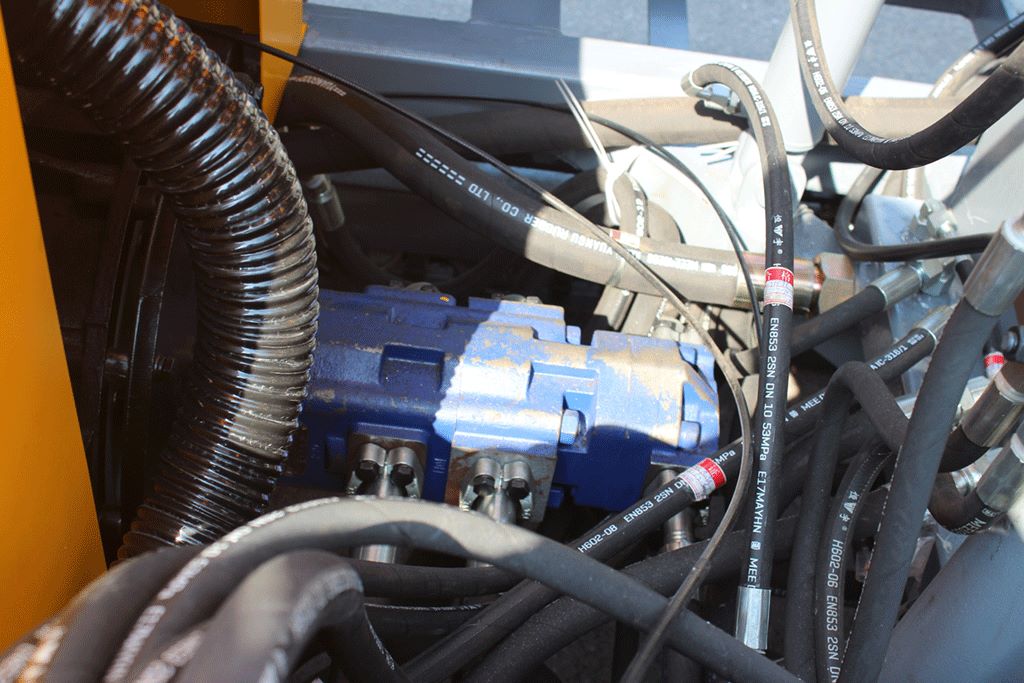

The High-Pressure Gear Pump

Complementing the powerful engine is the high-pressure tools pump. This component is crucial for the hydraulic system, which is the "circulatory system" of the rig. The pump generates the titanic hydraulic pressure required to operate the rotary head, elevate and lower the mast, and control the outriggers. A high-quality, high-pressure pump ensures easy and responsive control of all hydraulic functions, providing the unique power needed for one-of-a-kind drilling phases. This reliability is a key feature to look for in professional-grade water properly rigs for sale, as it directly impacts control, safety, and operational smoothness.

Foundation and Stability: Ensuring Safe and Accurate Drilling

Power is vain without control. A drilling rig must be a secure platform to ensure accuracy and safety for the duration of the drilling process.

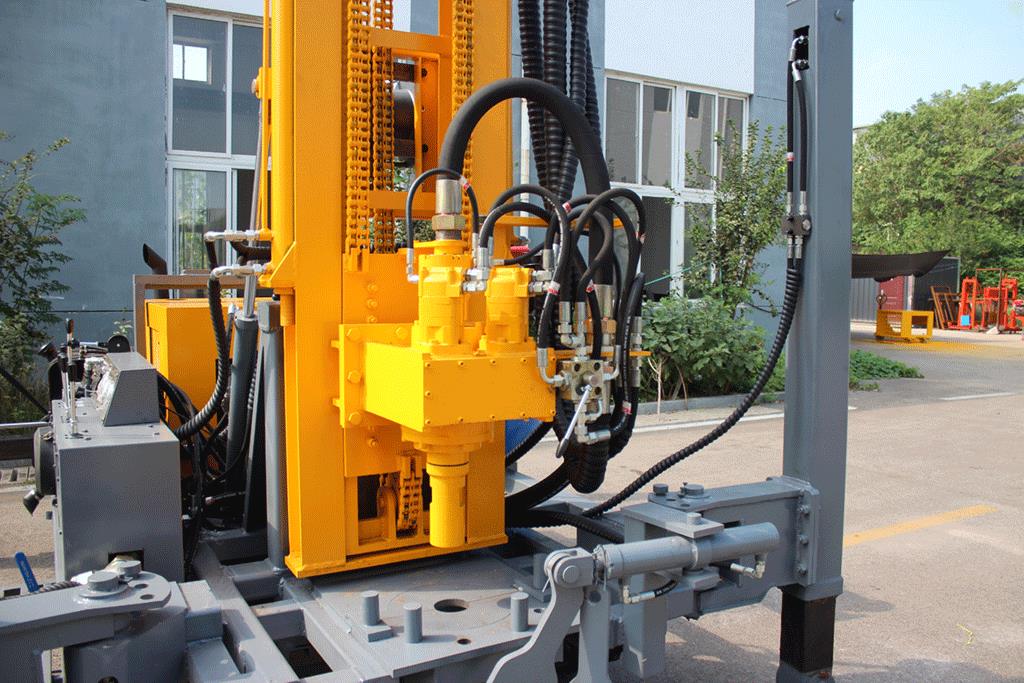

Extended Outriggers for Superior Stability

Extended outriggers that increase loading width are a critical plan feature for any modern drilling rig. These outriggers dramatically amplify the rig's footprint, creating a wide, stable base that prevents transferring or tipping during operation. This is especially essential when the drill encounters uneven resistance underground or when operating on sloped or uneven terrain. Enhanced stability protects no longer only the machine and the crew however also ensures the borehole is drilled straight and true. This feature is non-negotiable for serious contractors and is a popular mark of quality on reputable well drilling tools for sale.

The Reinforced Carriage

Beneath the stability system lies the reinforced carriage. This is the rugged chassis that helps the entire rig during each drilling and travel. A reinforced carriage is built from high-strength metal to withstand the incredible stresses of drilling, the weight of the mast and engine, and the rigors of transportation over tough job sites. It’s the backbone of the machine, designed for durability and long-term structural integrity. Investing in a rig with a strong carriage means investing in a machine constructed to last for years, a crucial aspect when evaluating water well rigs for sale.

The Drilling Powerhouse

This is where the magic happens. The drilling machine is what transforms engine power into a functional well.

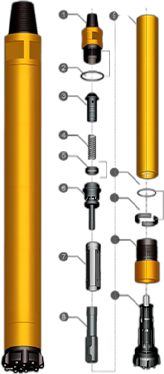

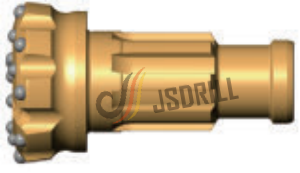

High-Focus Powerhead with 170-200 RPM

The High Focus powerhead with 170-200 rpm is the enterprise end of the operation. Also known as the rotary head or pinnacle drive, this component is responsible for rotating the drill string and the connected bit. An optimal RPM range of 170-200 offers versatile speed for various drilling techniques and geological formations. This allows operators to adjust their method for soft soil or hard rock, making sure efficient progres