Well drill rig

Mastering Drill String and Bit Operation: A Critical Precautions Guide

Pre-Drilling Inspection: The Non-Negotiable First Step

Before initiating any drilling activity, a meticulous inspection of the bottom-hole assembly (BHA) is paramount. A failure here can lead to a "fishing job" to retrieve lost tools, or worse, an abandoned borehole.

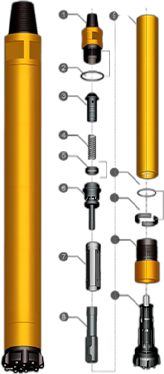

Connection Integrity: Visually and physically check that all connections for the down-the-hole impactor, follow-up drill string, casing, and casing shoe are secure and properly torqued. Even a slight looseness can lead to thread damage or component separation underground.

Eccentric Bit Function: Manually verify that the eccentric drill bit moves freely and rotates without obstruction. Its ability to pivot is crucial for both drilling and retraction. A seized bit is a primary cause of failure.

Ventilation Check: Ensure the air circulation system is clean and functional. Proper ventilation is essential for cooling the bit, removing cuttings, and preventing the bit from becoming packed with debris. A reliable air system is a key feature to look for in any well drill rig for sale.

Investing in a high-quality water drill rig for sale from a reputable manufacturer often means better-made threads and more robust components, making this pre-check more straightforward and reliable.

Operational Vigilance: Monitoring the Drilling Process

Once drilling commences, the operator's focus must be unwavering. The rig's sounds and gauges provide a constant stream of data about conditions at the bottom of the hole.

Monitor Casing Follow-Up: Pay close attention to how the casing is following the drill string into the formation. Any binding or hesitation needs immediate attention.

Observe Dust Removal: The efficient removal of rock dust from the hole is a key indicator of proper ventilation and bit function. Ineffective dust removal signals a problem that must be addressed before proceeding.

Controlled Blowout: When clearing the hole, control the upward movement of the drill string carefully. The goal is to allow adequate time for compressed air to evacuate cuttings without causing a collapse of the borehole walls.

Avoid Excessive Force: Never use excessive downward force or torque. Let the weight of the string and the action of the impactor do the work. Forcing a water well drill rig can lead to premature bit wear, string fatigue, and getting stuck.

The Critical Retraction Sequence: Safely Recovering the Drill String

The process of retracting the eccentric drill bit is one of the most delicate operations. Incorrect procedure is a common reason drill strings get stuck. Follow these steps precisely when a water well drilling rig has completed its section or requires a bit change.

Clean the Hole: First, always clean the hole thoroughly by blowing air to remove all rock debris from the bottom. A clean hole bottom is the first step to a successful retraction.

Stop Rotation and Lift Slowly: Cease rotation and begin to lift the drill string slowly and gently. Use only the force required to lift the string's weight.

Engage the Casing Shoe: Continue the slow upward movement until the back of the eccentric drill bit contacts the front of the casing shoe. You will feel a slight resistance.

Reverse and Lift: At this point of contact, start reversing the drill string at a low speed while simultaneously maintaining a slow, steady upward pull. This reverse rotation is what triggers the eccentric bit to retract into its closed position.

Confirm and Retrieve: Once the drill string lifts smoothly, the bit has successfully retracted. You can now cease reverse rotation and lift the entire string out of the hole using conventional methods.

Troubleshooting a Stuck Drill Bit

Despite best practices, sometimes excessive rock debris can jam the rotating mechanism of the eccentric bit, preventing retraction. If repeated, gentle attempts to lift the string fail, do not apply brute force.

Re-Clean the Hole: Resume supplying pressurized air to clean the hole again, ensuring you agitate the bottom to dislodge any packed material.

Briefly Re-engage the Hammer: Operate the down-the-hole hammer for a very short burst (a few seconds). The vibration from the hammer can often shake loose the debris jamming the bit mechanism.

Re-attempt Retraction: After this, stop rotation and slowly attempt the standard retraction sequence again. The combination of a clean hole and percussive vibration is often enough to free the mechanism.

Understanding these precise operational nuances underscores the value of a well-designed machine. When considering a new water well drill rig for sale, prioritize models known for smooth, controlled hydraulics and responsive controls, as these features are essential for executing these delicate procedures successfully.